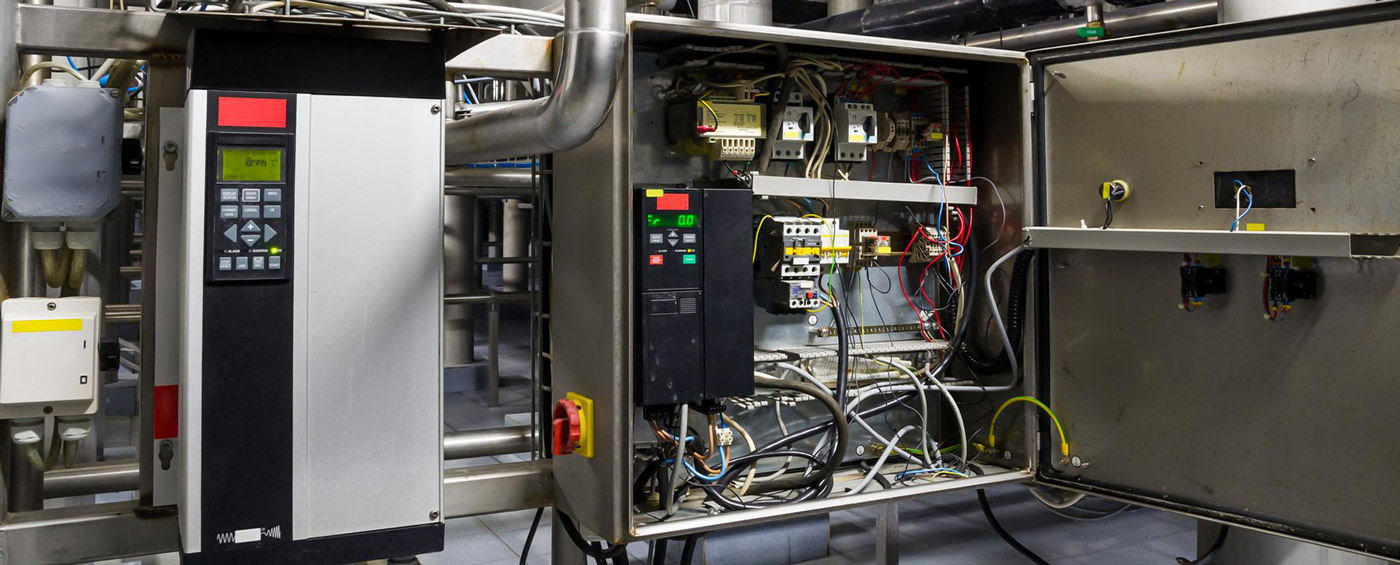

Many motors run at a constant speed, even when there is little demand to do so. This operation can waste energy and wear out equipment faster. An energy-efficient variable speed drive (VSD) slows the fan or pump down when the load decreases, saving energy.

The Sponsors of Mass Save offer incentives for new variable speed drives, as well as replacement of existing motors and drives that are aging or less efficient.